Supply Chains in the Era of Large Language Models

Dr George Bargiannis

Subject Area Leader, Department of Computer Science

The School of Computing and Engineering

Introduction

The apparent success of AI solutions powered by Large Language Models (LLM), the deep learning technology behind ChatGPT, Google Bard and similar solutions, has driven both researchers and practitioners to explore the extent to which similar technologies can benefit their domains and address long-standing or emerging problems.

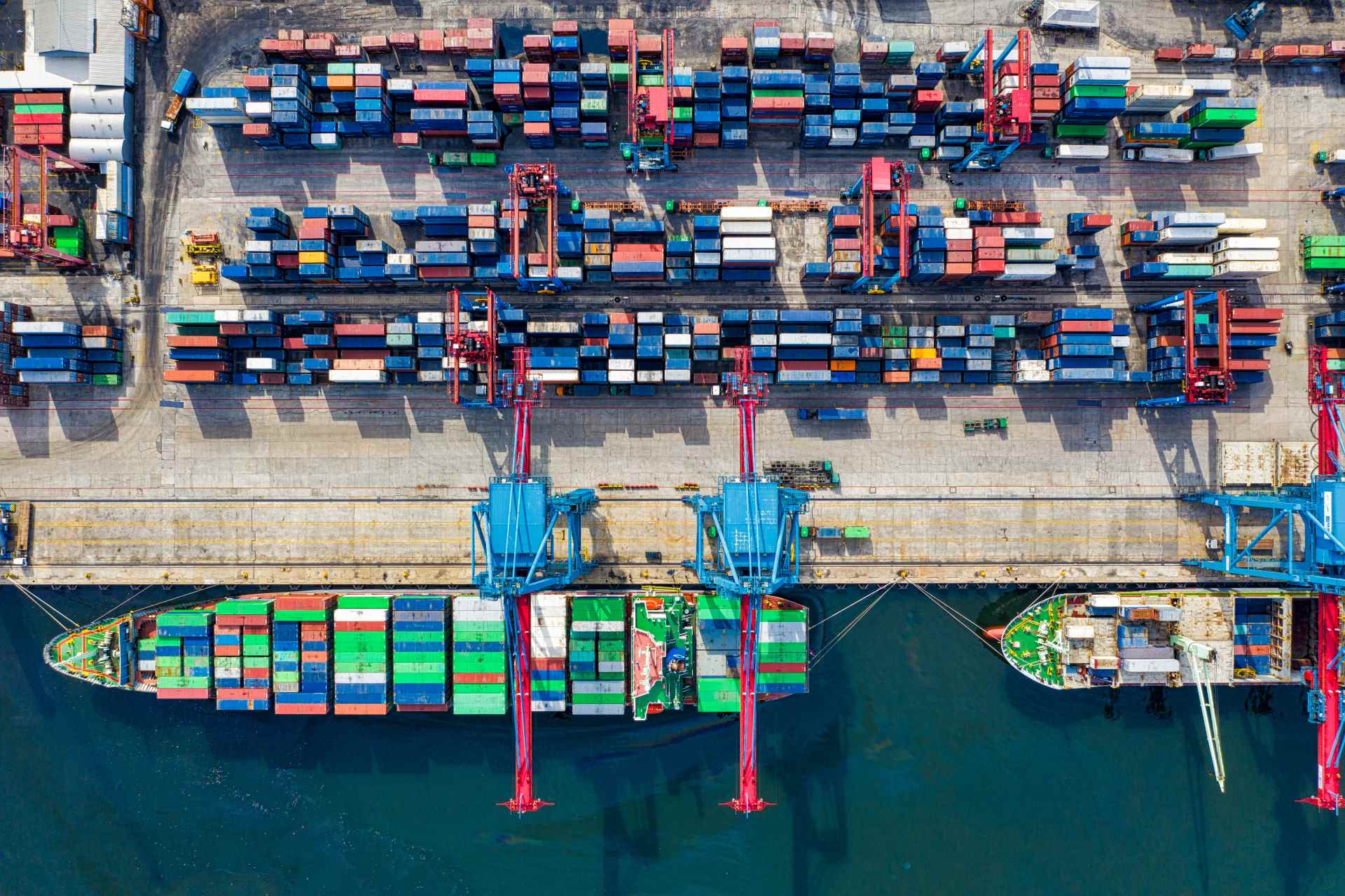

One such domain is supply chains, where AI has recently begun to be investigated but is far from reaching its potential. This potential covers a wide range of aspects, from customer support and procurement, to resilience.

The main question to ponder here is what the potential impact of LLMs in supply chain management can be and whether the hype surrounding it will obscure the true extent of its capabilities in a supply chain context.

The Potential Challenges

As with all relatively new AI technologies, it is hard to establish the potential impact LLMs may eventually have, before extensive and thorough validation and testing. For instance, Google Bard, was clearly shown to not be ready for wider real-world use, when it recently gave a wrong answer in a promotional video.

In general, LLMs are directly dependent on the availability of vast amounts of data. Their success rests on their ability to self-improve by learning to filter out low quality or unsuitable information and curate both their input and output. Existing LLMs, such as GPT-4, are still far from being considered fit for purpose for commercial use, certainly not within a supply chain setting. This is because the data they are trained on are unlikely to be of direct relevance to the day-to-day operations of a particular supply chain as most of these data are not publicly available.

A bespoke version, on the other hand, trained on data provided by a particular brand or a network of affiliated brands, will be more likely to assist in tasks such as supplier selection and evaluation, by quickly assessing candidate supplier capabilities and track record based on historical information.

End-to-end Traceability and Visibility

In the case of supply chains, availability of data to create bespoke LLMs is a significant barrier. End-to-end traceability and visibility across the supply chain is still a major challenge and achieving it would be a prerequisite for any LLM-based effort to be impactful in a particular supply chain or across supply chains.

The barriers to achieving it, however, are not primarily related to technology maturity, but rather to the unavailability of the necessary infrastructure and legislation. For example, it has only been a year since the EU Commission adopted a proposal (Proposal for a Regulation on Ecodesign for Sustainable Products) to create a Digital Product Passport. This is the backbone of any successful traceability approach, since it will ensure that every stakeholder related to a product will have access and contribute to data related to a product throughout its lifecycle.

Until traceability-related initiatives like the Digital Product Passport are up and running, technologies like ChatGPT will be unable to contribute to much improvement, as they rely on access to such data in order to be able to facilitate track and trace processes.

LLM-Powered Chatbots

In their current form, LLM-powered chatbots can assist in this context by tapping into collecting knowledge existing in the WebText dataset it has been trained on, which consists of 8 million publicly available web pages. They would, for example, be capable of listing standard quality control guidelines and processes, given that there is high likelihood for this information to be available in the web pages it had access to.

However, it should be noted that any further use of LLM-powered chatbots that goes beyond this, especially if it is intended to be used for tasks as specialised as predictive maintenance within a particular manufacturing process, will again depend on it being retrained on a different dataset, that is more current and more relevant. For example, an LLM trained on years’ worth of historical records of maintenance tasks will potentially be able to assist in monitoring (offline or online) an assembly line to detect and predict equipment faults.

Unlocking AI's Potential

From a broader perspective, the transformation potential of AI technologies within supply chains is endless and we have only really scratched the surface in terms of exploring how and where AI can be applied in the context of supply chains.

Integrating LLM-powered chatbots like ChatGPT into either customer-facing processes or internal processes such as supplier selection or manufacturing processes can facilitate finding answers to questions and making optimal decisions which can eventually lead to reduced operational and resourcing costs. However, wider integration and adoption of intelligent technologies in supply chains can only be achieved if these technologies have the ability to at least partially explain their responses.

Imagine the scenario of a procurement manager in a yarn production company asking ChatGPT which supplier to select for a particular fibre order? Would they be able to trust the response they receive if it’s not accompanied by a clear explanation that depends on specific criteria supporting that decision? Pure “black-box” deep learning models like GPT-4 are unable to provide clear reasoning paths showing why they provide an answer to a question.

Conclusion

In my opinion, the future of AI in logistics and supply chain rests on the development of hybrid solutions, ones that combine the vast data processing power of deep learning models with the explanation capabilities of knowledge-based models and solutions, such as knowledge graphs and logic-based reasoning. Such hybrid solutions are the main focus of supply chains related research conducted in the Centre for Autonomous and Intelligent Systems at the University of Huddersfield.